We have spent many years working to develop systems for reinforcement solutions within the sanitary ware and other industries.

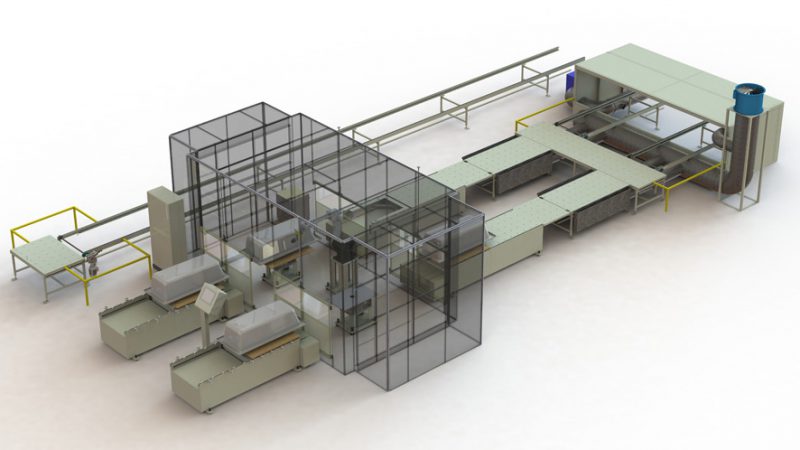

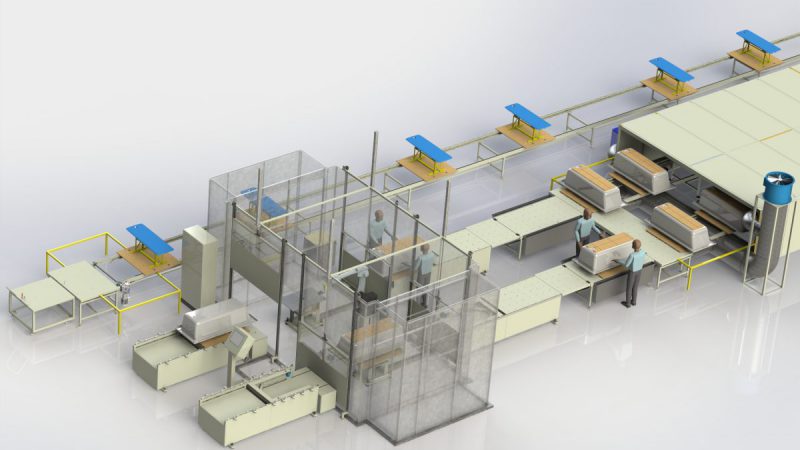

We can design and build the complete package for the customer requirements, with everything included.

We can design and build the complete package for the customer requirements, with everything included.

We design and manufacture production lines to use the latest composites application equipment for manual spraying systems.

These systems can be designed to match customer’s exact requirements, and include material monitoring, product transfer conveyors and fume extraction.

We have integrated robotic technology to offer efficient and controlled reinforcement solutions to the sanitary ware industry and others.

Pre-programmed robotic spraying allows for significant material and labour savings, as well as offering a consistent quality product.

Our user friendly software works alongside the robotic controller to ensure an efficient and automated product delivery system.

Material delivery is contained within an extraction booth to ensure operator safety and extremely efficient fume extraction.

The RF- Resin Filling System is designed to accurately mix filler such as calcium carbonate (limestone) into resin, and automatically deliver the mixed material to the composites application equipment.

The benefits of adding filler to resin are to enhance performance and reduce manufacturing costs; it also reduces shrinkage and improves thermal stability.

The CT series of Curing Tunnels are designed to provide controlled conditions for the curing of polyester resin and glass reinforced products,whilst integrating perfectly with the rest of the production facility.

Transit conveyors and fume extraction can also be supplied.